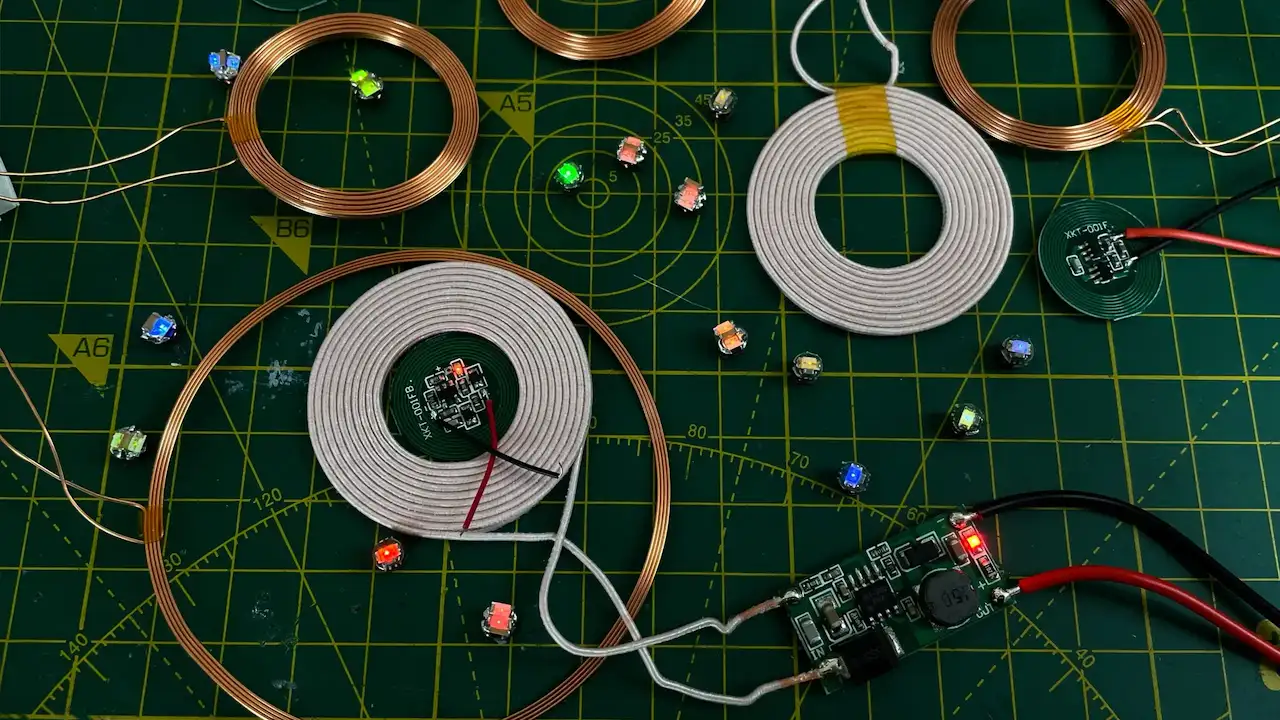

Ever since discovering these crazy wireless LEDs I’ve been messing around with wireless charging technology. So far I’ve been a bit disappointed with what I’ve been able to do, it’s been great for making LEDs light up, but my attempts to use it for anything serious have either resulted in me burning out the transmitters, or releasing the magic smoke from the circuit I’m trying to power.

So I decided to bite the bullet and get a proper set of wireless charging PCBs. If you want to watch a full video of the experiments in this blog post then you can do so here - it’s definitely worth it!

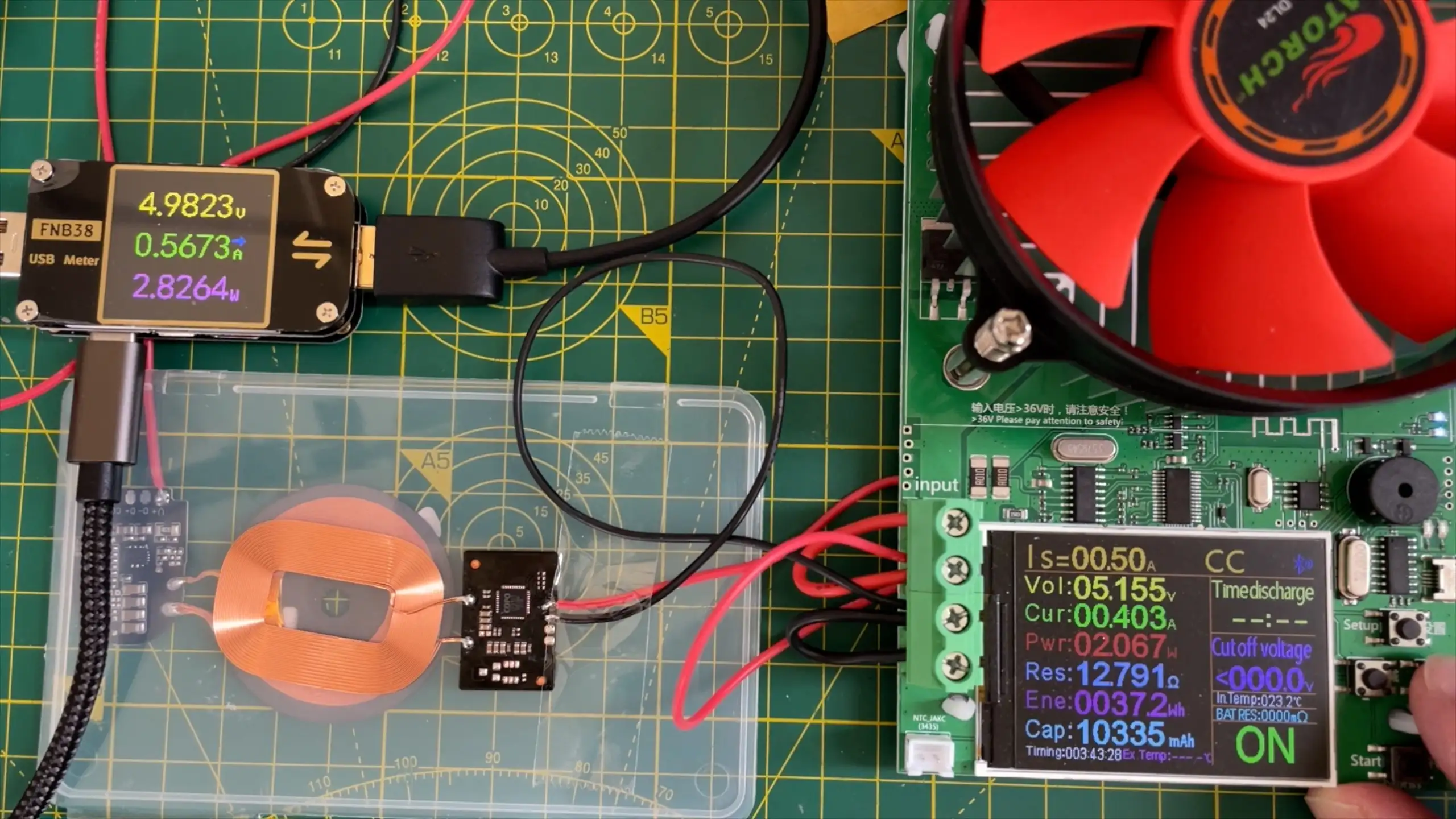

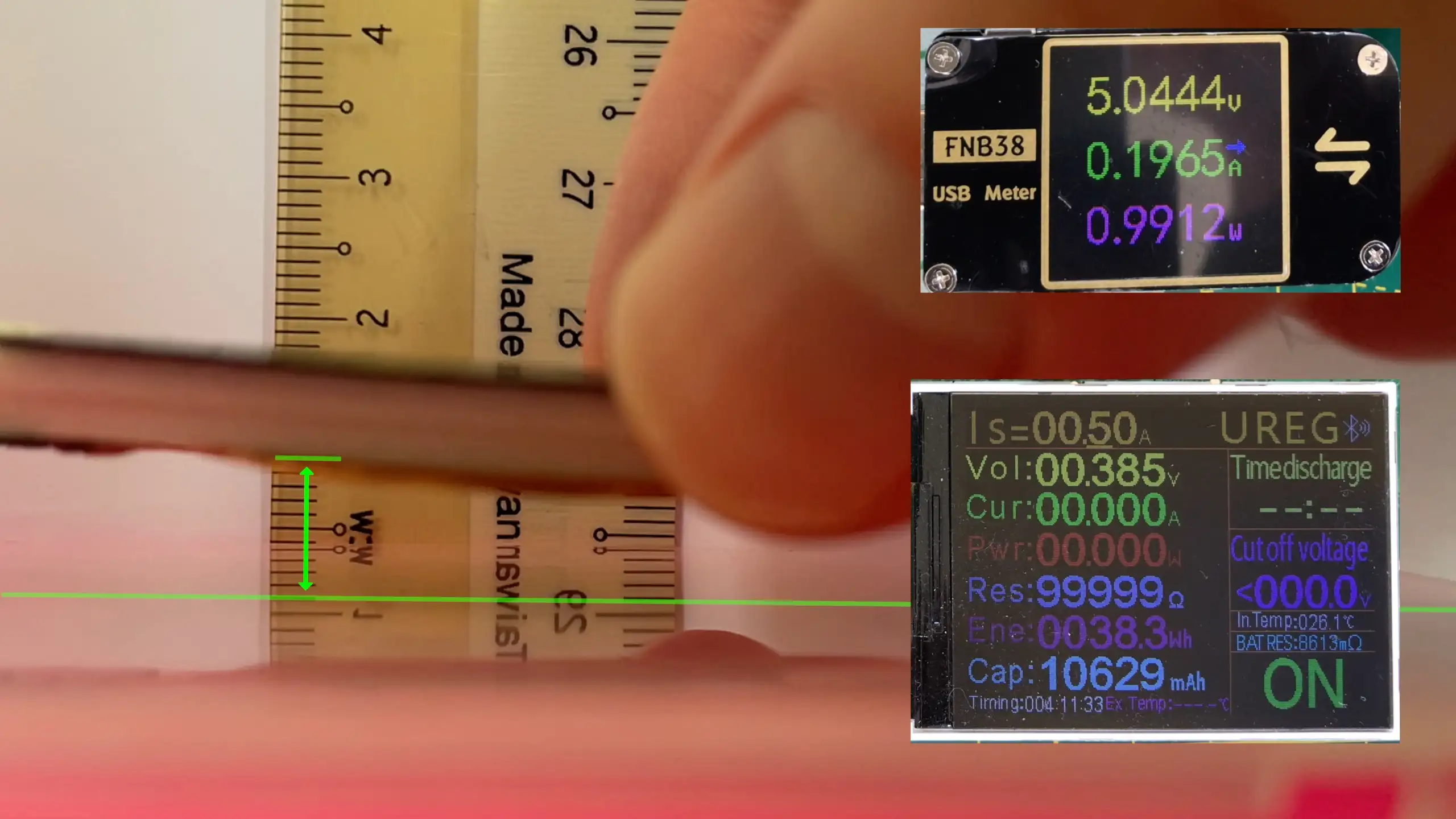

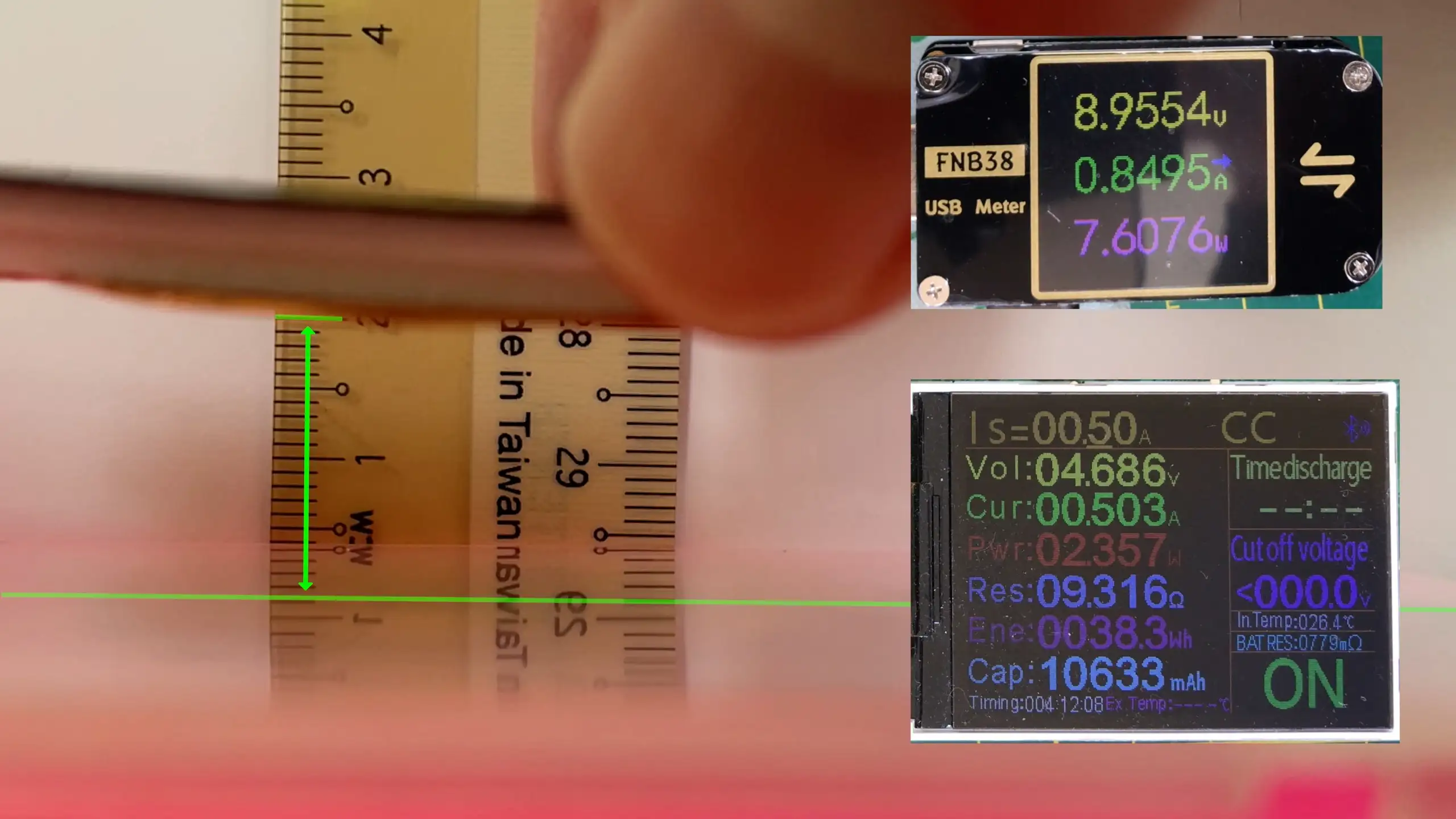

The transmitter board I have can take 5v, 9v and 12v as input and in theory with the receiver board I have we should be able to get up to 1.5A at 5v out of it. To test this I’ve hooked the transmitter up to my USB power monitor and the receiver up to my electronic load. The USB power monitor is pretty cool, it will monitor the voltage, current and power, and it also lets me trigger the various USB Power Deliver and Quick Charge modes.

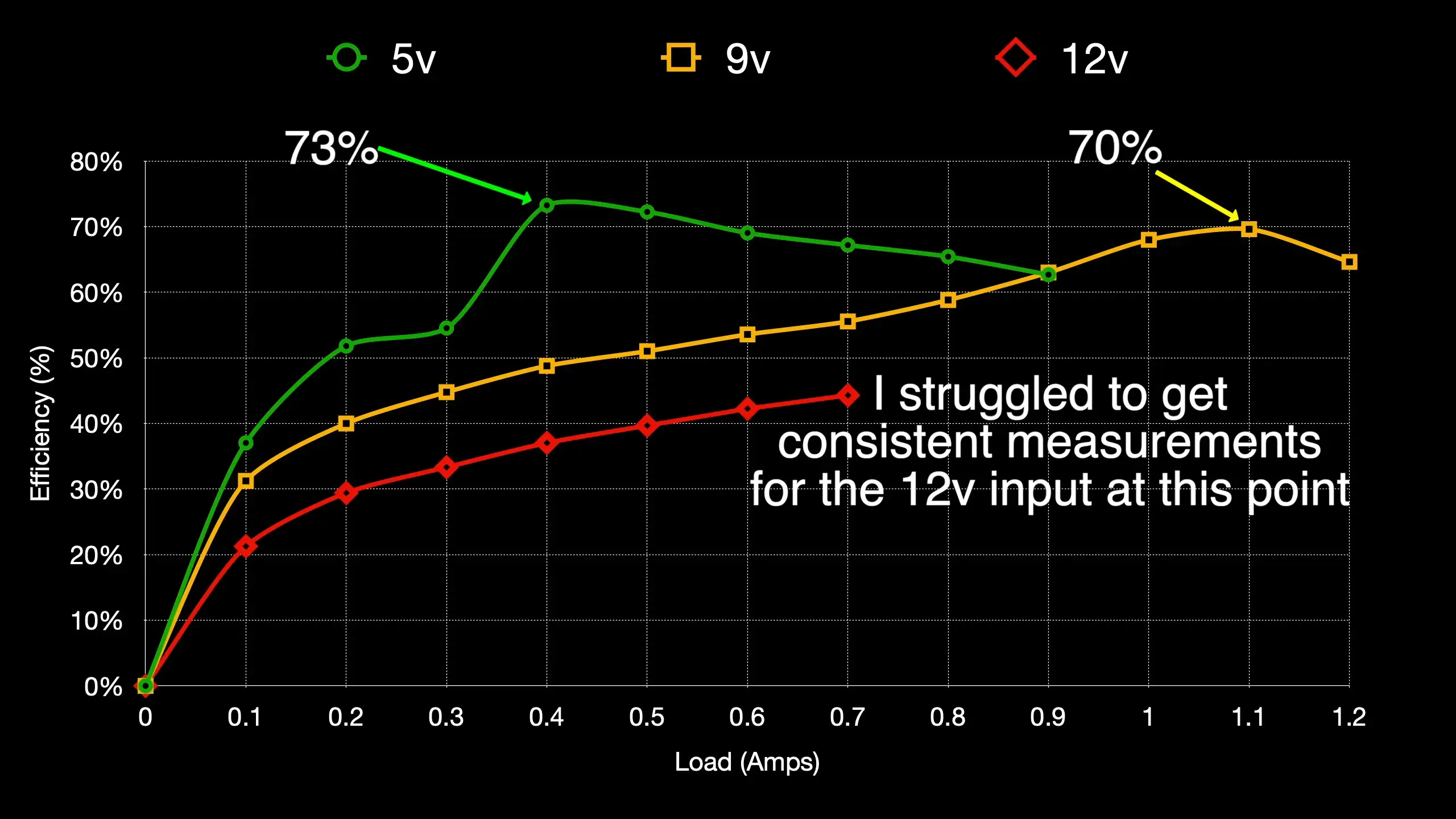

I’ve run through the three different voltage inputs with the electronic load set to different load currents and generated the following graph. What was quite interesting is that I struggled to get the 12v input to work consistently, it would often fail at quite low current loads.

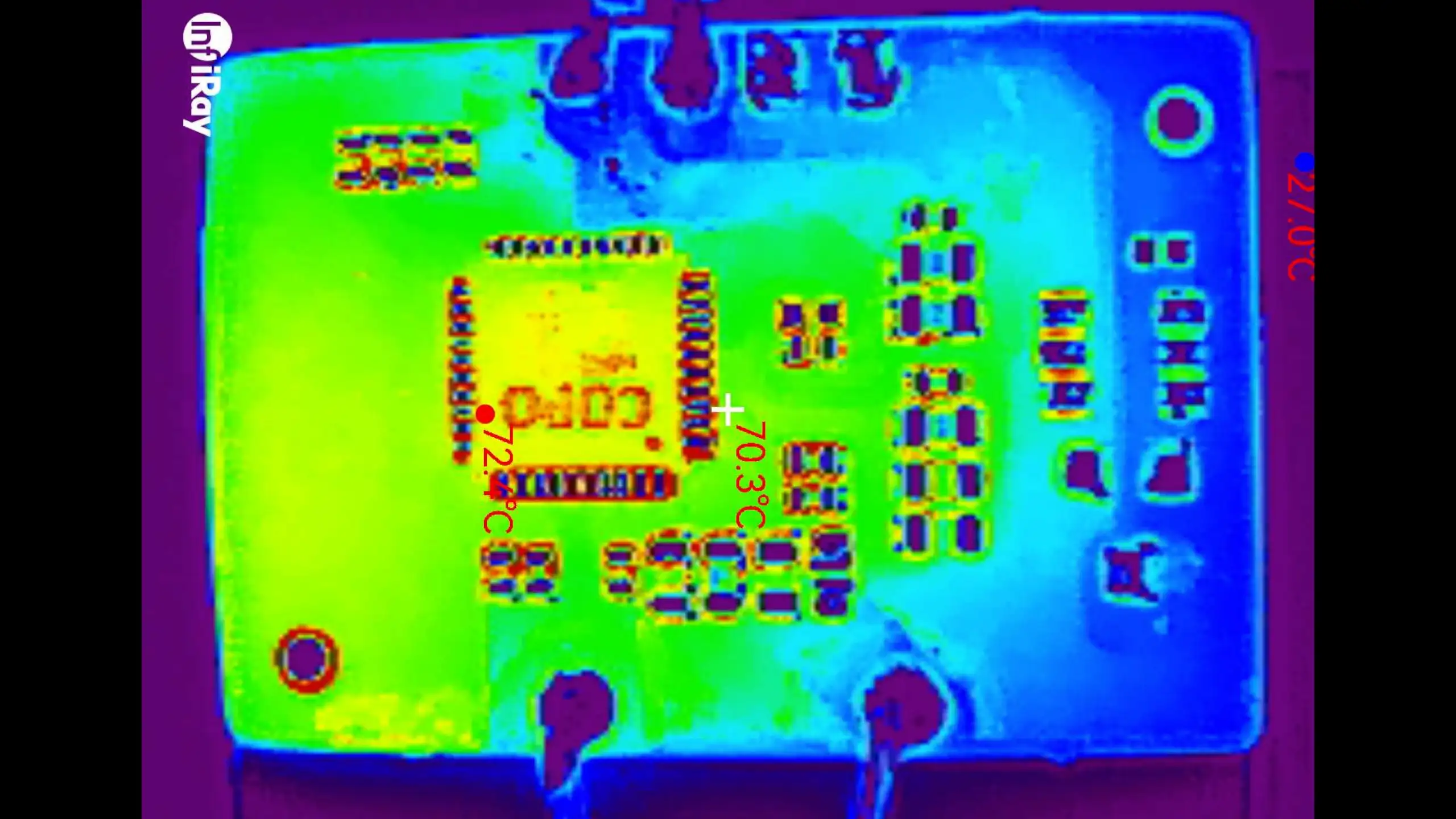

With the 5v input, we get maximum efficiency of 73% at a load of 0.4Amps. With the 9v input, we get just under 70% efficiency at 1.1 amps. With the 12v input, I couldn’t get it to work consistently above 0.7Amps and the efficiency was very low. I also noticed that the receiver board was getting quite warm when the transmitted was using 12v. The board was getting up to almost 80 degrees C, which is a bit too hot for my liking. When running at 5v or 9v it only got up to about 50 degrees C.

The efficiency I’m measuring is pretty close to the listing on AliExpress - which says we should be able to get 75% - so we are facing one of those rare occasions where the listing is actually accurate!

I also tried to measure the range of the transmitter and receiver. Running at 5v I got around 1cm of range, at 9v I got around 1.5cm - 2cm of range. I didn’t try and measure the 12v range as I didn’t really trust it.

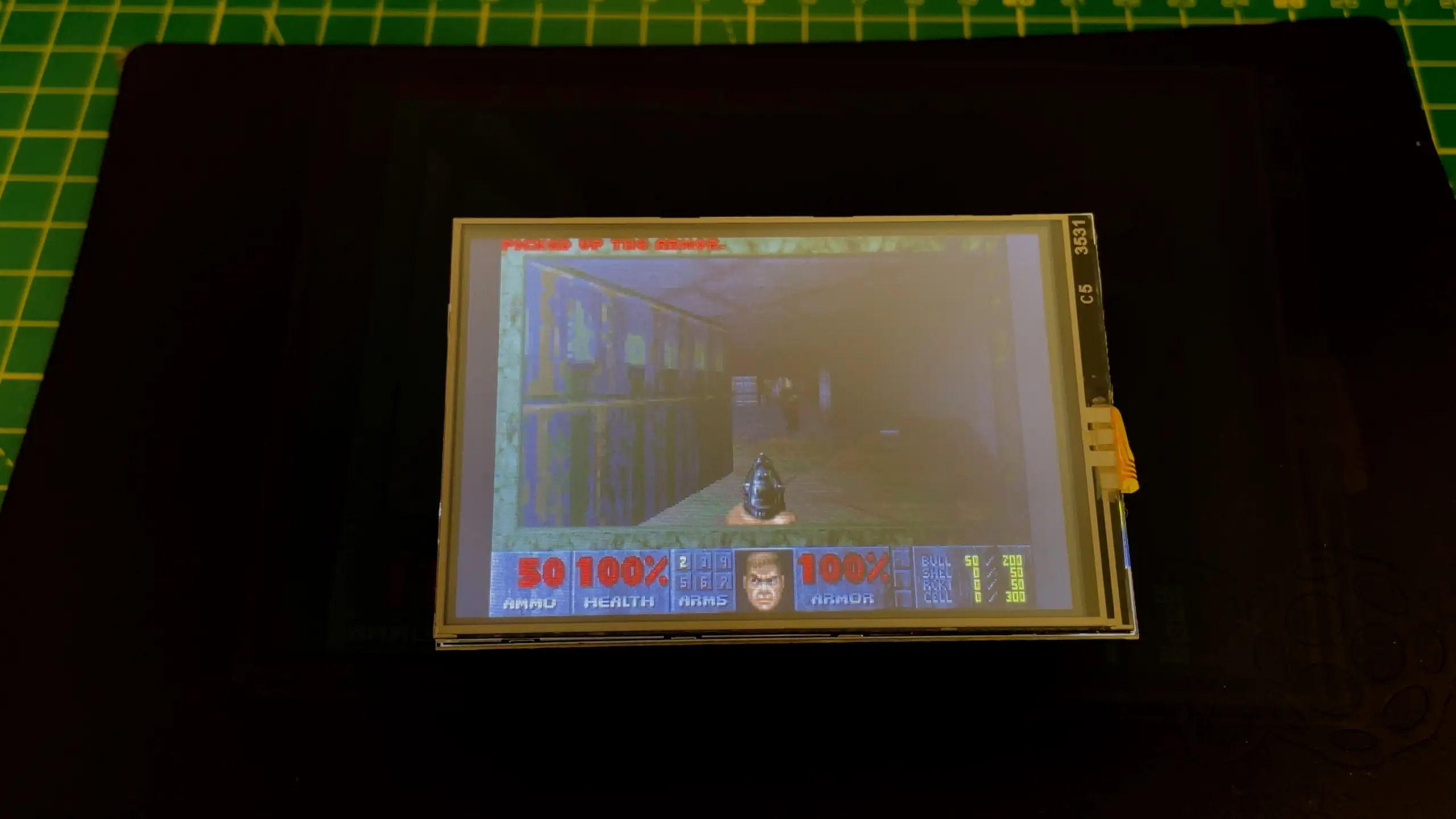

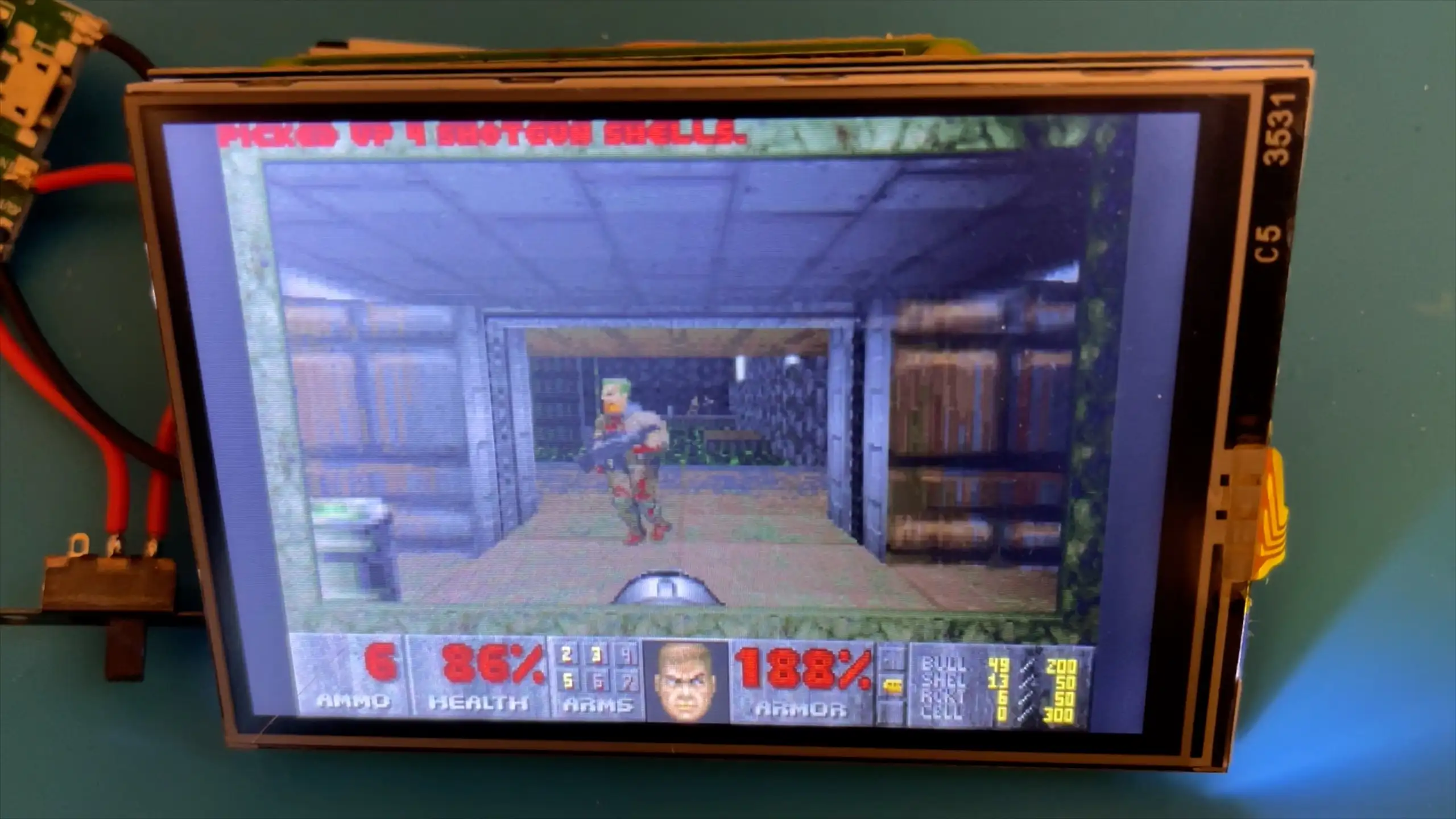

I thought it might be fun to try and run a Raspberry Pi Zero W2 with the transmitter and receiver boards. To make it a real test I’m going to run Doom on the Pi with a nice TFT screen. To check if this was even feasible I ran the Pi with it connected to my USB monitor and it peaks at around 0.65Amps when running Doom. So it should work without any problems.

And after a bit of fiddling it works really well, we can run the Pi over wireless power.

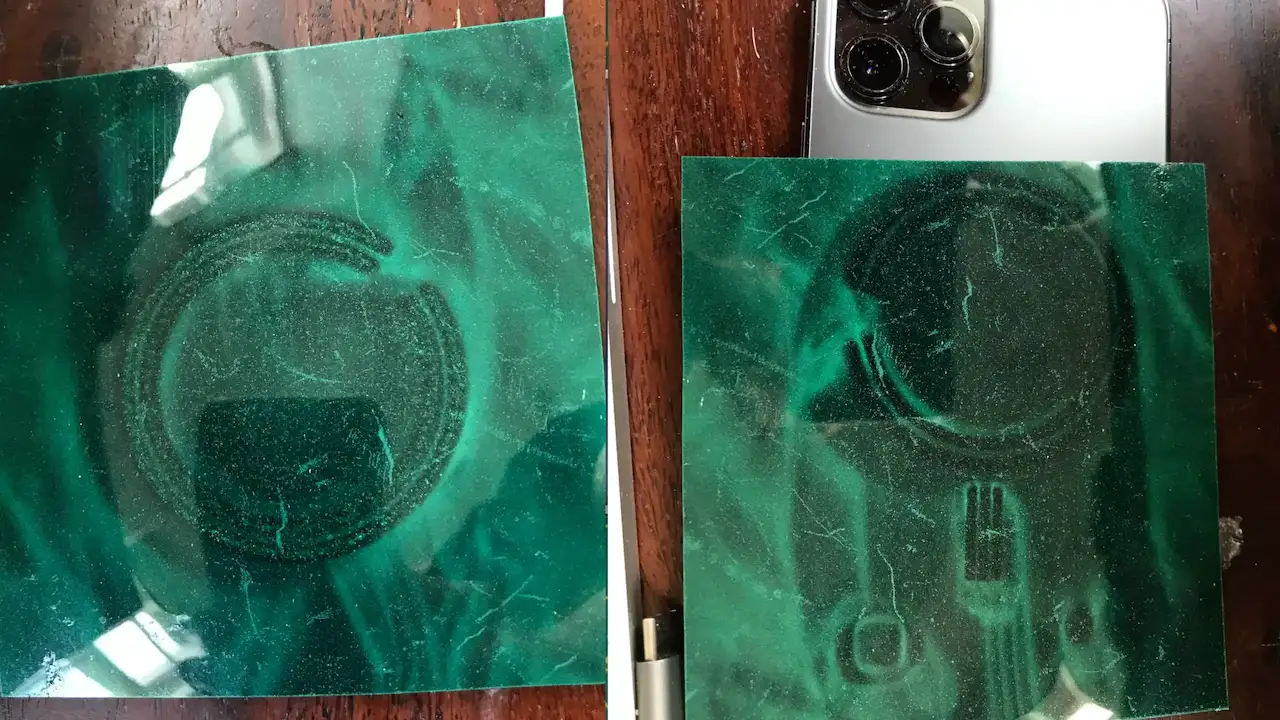

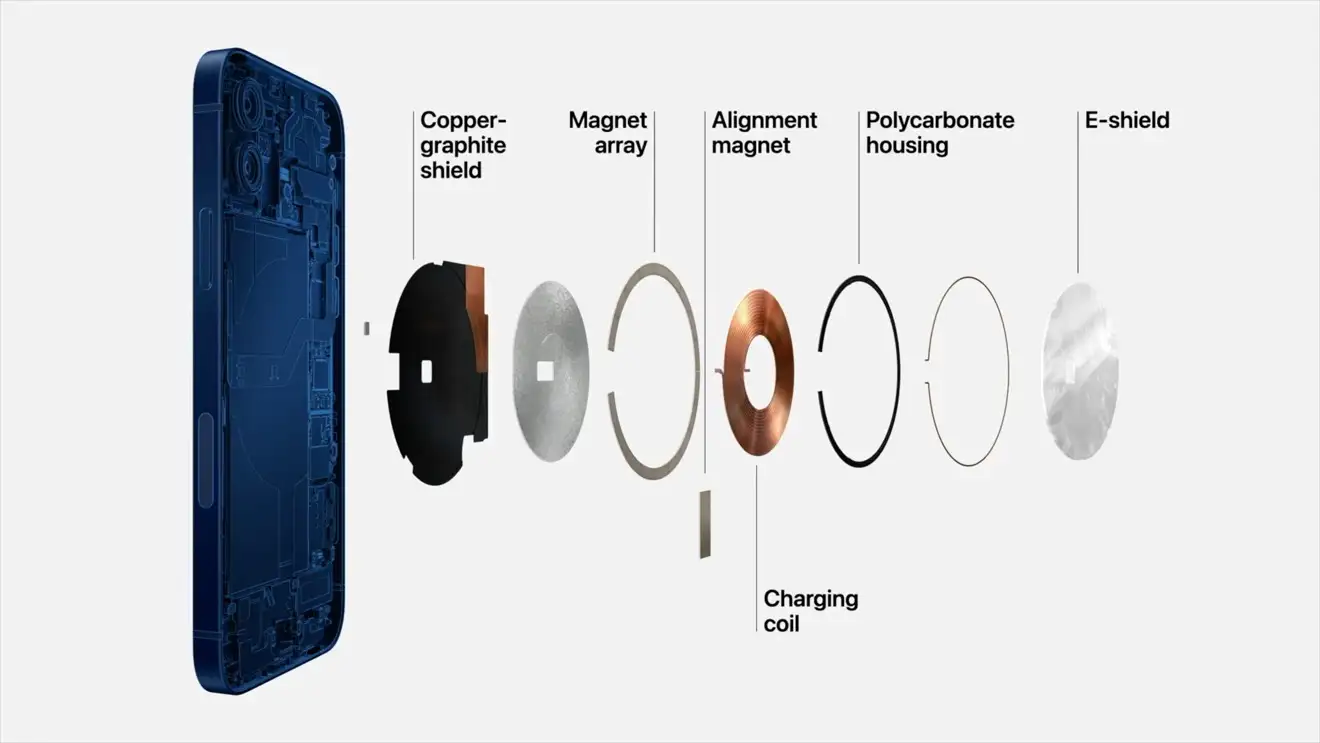

One of the things I did find, is that it’s surprisingly hard to get good alignment of the coils when you can’t see the transmitter. This does explain why the iPhone has a bunch of magnets in it to help line it up with the transmitter. I’ve used one of my magnetic sheets to visualise the magnets in the phone and phone charger.

There’s also this nice exploded view of the iPhone showing the magnets.

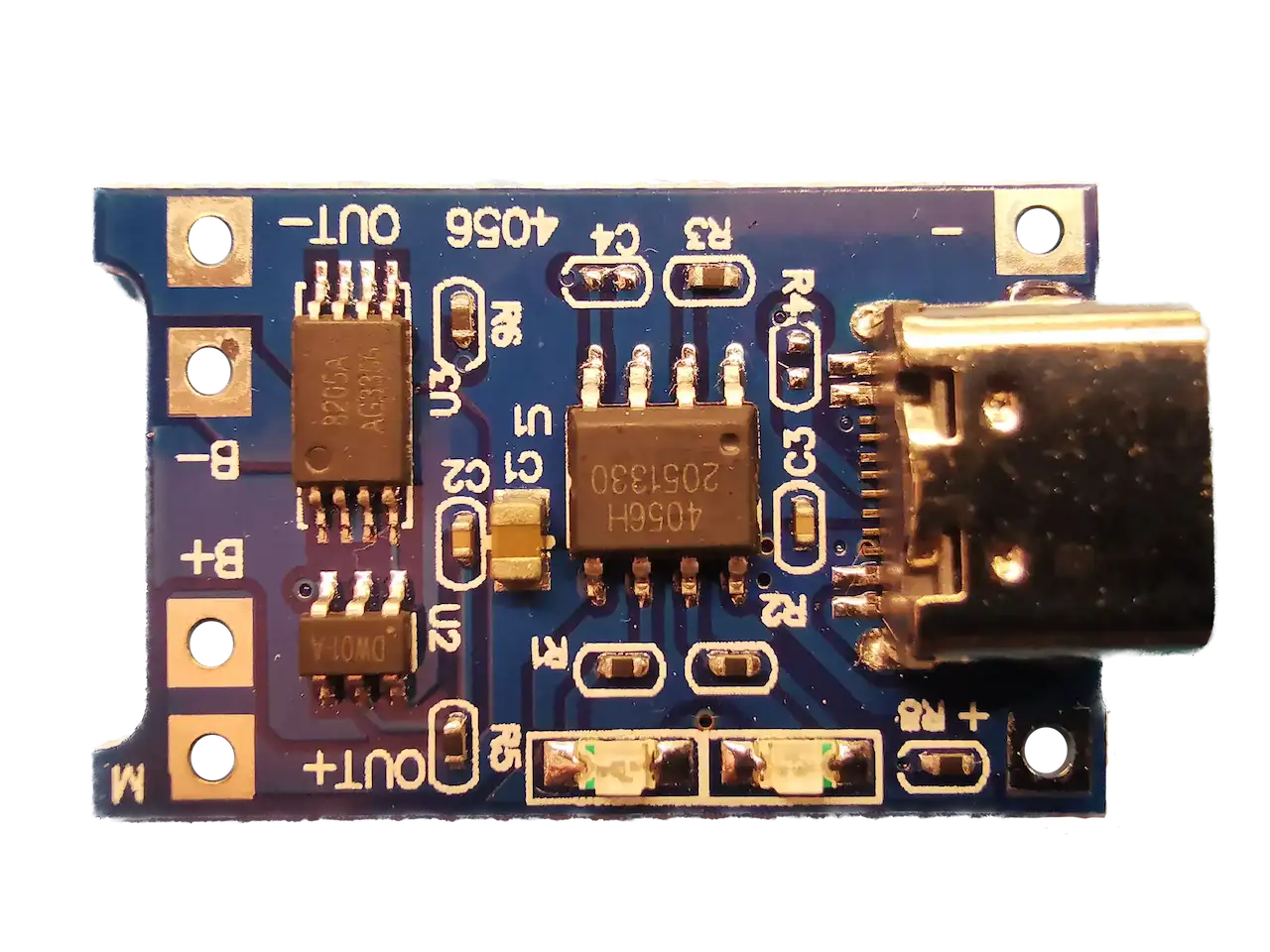

So, it’s pretty cool to power the Pi completely wirelessly, but it is ultimately a bit pointless. As soon as we move the Pi away from the transmitter coil it stops working. We really do need to actually have a battery that is charged by the receiver. I’ve got a whole bunch of battery charging boards based around the TP4056 chip.

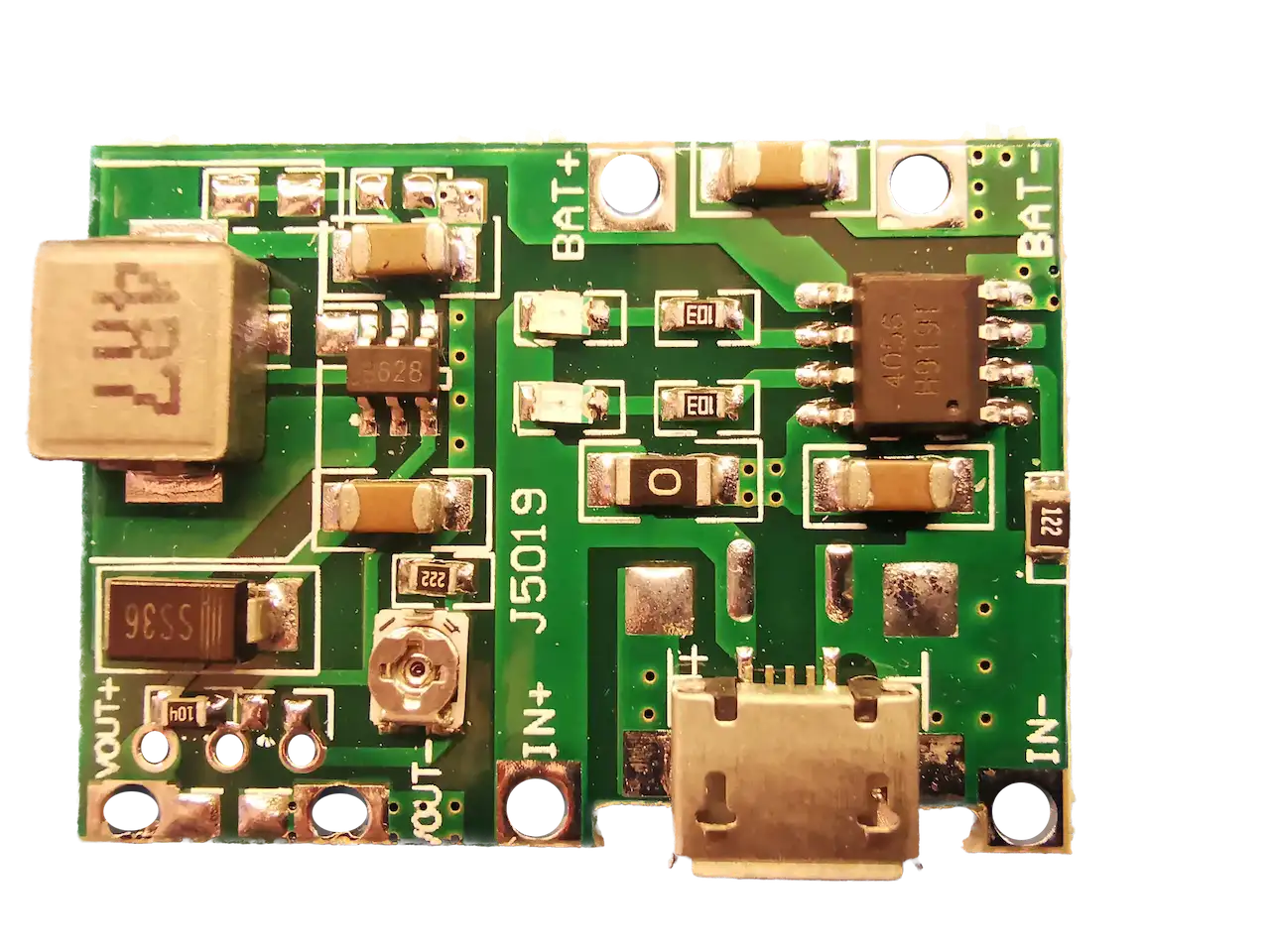

But I’ve also got a bunch of boards that use the TP4056 chip and have a built-in boost circuit. The potentially nice thing about having a boost circuit is that our battery can go very low and we’ll still be able to use it to power the Pi.

Unfortunately, the first board I tried boosted the battery voltage without any problems, but I could only adjust it to 5.66 volts. The Pi’s power management IC can only take up to 5.5 volts, so although we’re close, I’d like to give it 5v - I really don’t want to blow up my Pi as they are still quite hard to get hold of!

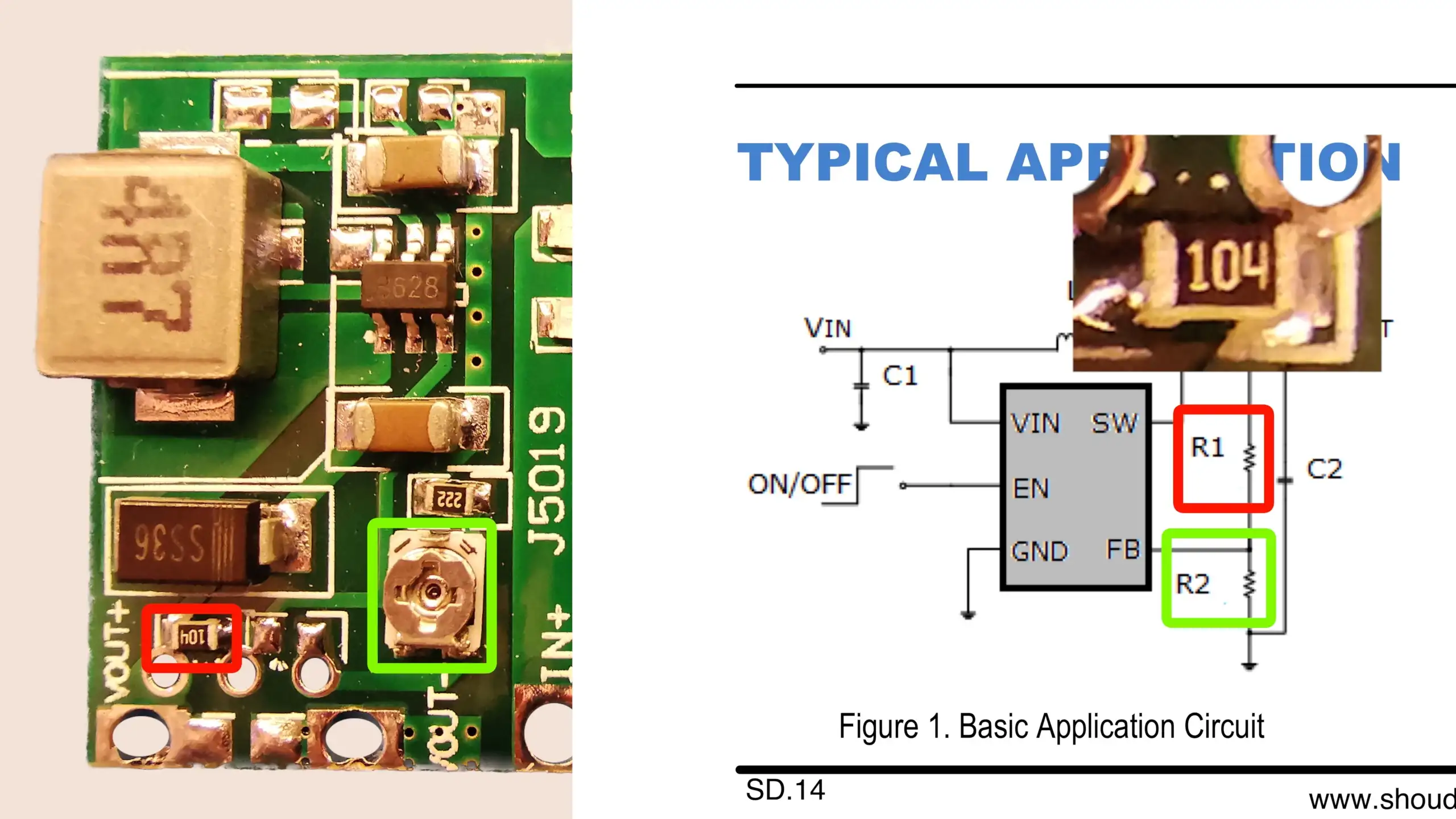

Looking at the boost converter’s IC datasheet, the voltage is controlled by this resistor divider.

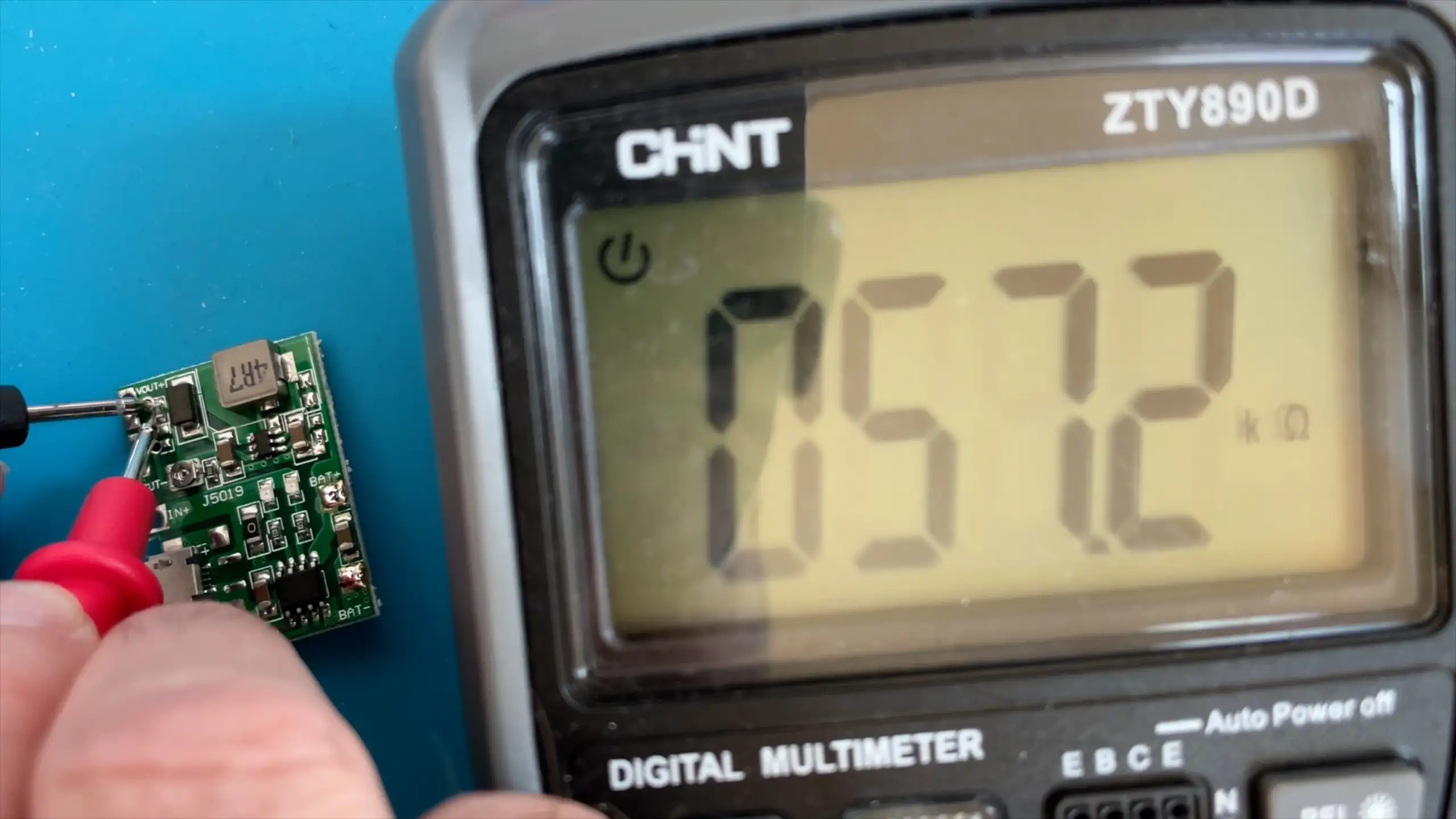

The top resistor has the code 104 - which should be 100K ohms. But when I measured it in the circuit I only got 57K. The trim pot is also only going down to 9.9K - so there’s no way we can get the voltage we need.

Fortunately, we can add some additional resistors to the board, so I’ve ended up soldering a 100K in parallel with the top resistor. With this in place, we can get 5v out of the boost converter.

With the battery hooked up, it charges up via the wireless transmitter. And eventually the battery gets up to full charge.

It’s now easy enough to hook it up to the Pi with a switch to turn it on and off.

Of course, with it all working, I realised it would probably be much better to split the charging and boost board into two separate modules. We can then easily switch off the boost converter. If we then it will drain the battery over time. But that’s something for another day when we’ll add sound and a controller to make the ultimate wireless Pi Doom machine!

There’s a full video of this blog post available here - it’s worth a watch as there’s a lot more detail in it.

You can buy the Infrared camera I’m using here.

The nice USB power meter is this one: AliExpress, Amazon.

The wireless power transmitter is this one.

And the receiver is this one.